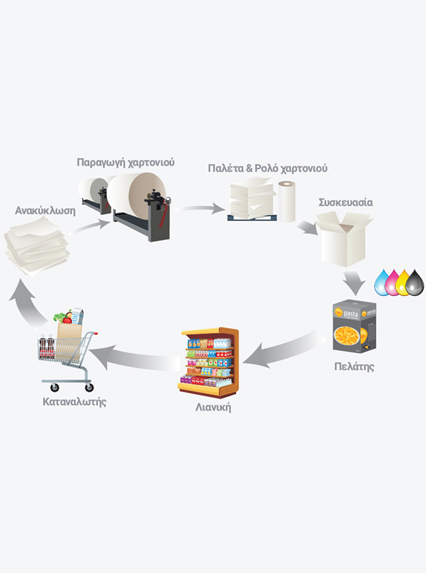

LIFECYCLE OF CARTONBOARD

-

The process of producing MEL cartonboard was organised with the aim of minimising waste and energy consumption. Recycled paper is the key raw material used to manufacture cartonboard. By making cartonboard out of 100% recycled paper and using renewable energy sources, we have created a closed, sustainable lifecycle for the product. MEL’s chief responsibility in practice is respect for the environment. Recycled cartonboard – the most sustainable packaging solution.

THE CARTONBOARD JOURNEY

-

-

1. Paper for recycling is transported by special lorries to MEL’s warehouses.

-

2. Selection of suitable paper.

-

3. The paper is pulped by mixing it with water in special pulpers.

-

4. The pulp is then passed through centrifugal filters and pressure sleeves to remove any foreign bodies (plastic, glass, metal objects, etc.).

-

5. The clean paper is de-inked, whereby any ink is removed.

-

6. The clean paper pulp is then dehydrated, dried and rolled up into large rolls.

-

7. The recycled cartonboard is ready to assume a new, useful form.

-

8. Recycled paper has seven lives! The same paper can be recycled up to seven times (without the fibres losing their properties).